ABOUT US

Sunny Plastics Technology Ltd is a technical oriented enterprise that integrates research and development, design, production, sales, and after-sales service. We strive to build an intensive, efficient, and modern enterprise, dedicated to supply high-precision products in the industry. After years of experiencing reputational managing and technics accumulation, we have advanced production technics, skilled industrial workers, and top scientific researchers, constantly developing high grade products so to providing clients with reasonable and efficient product solutions at quickest time and any time. Our company is keeping focusing on techology R&D, providing continuous R&D investment to go ahead with the competitive up-to-date products and correctly forecast the future market directions.

The company is currently stepping in two major divisions:

Divison of precision mold manufacturing and precision injection molded parts manufacturing, as well as division of plastic packaging with shrink films includes PET shrink film, POF shrink film, PE shrink film, and stretch film.

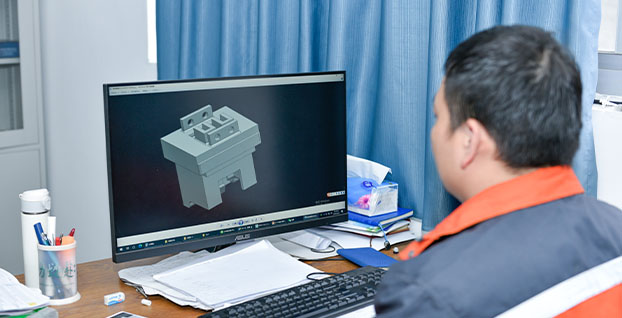

1. Precision molds and precision injection molding are a comprehensive technology company and professional manufacturer that integrates research and development, production, and sales of precision molds and precision injection molding. We also have the ability to research and design molds and fixtures, as well as processing capabilities. The company holds the NSF-ISR certificate, has passed ISO90001 and ISO16949 certifications, and has excellent product quality. It has been a supplier to world-class companies such as Apple, and is a trustworthy and ideal worry free cooperative enterprise.

2. The company is also involved in the field of shrink plastic packaging, mainly for shrink film packaging, including PET/PETG heat shrink film, POF heat shrink film, PE heat shrink film, and winding film. It has a first-class production line, among which the PET shrink film production workshop is a 100000 level dust-free workshop, with an annual production capacity of 20000 tons. The warehouse adopts a constant temperature warehouse to ensure that product quality is not damaged during storage. The product quality has passed SGS certification and testing, FDA and EU certification, and is highly praised by users. PET shrink film products are mainly used for the production of shrink labels and other purposes, while POF and PE shrink films are mainly used for packaging and other purposes of beverages, food, gifts, electronic products, and other industrial products.

Welcome all kinds of customers to express their needs. We will provide you with satisfactory products and attentive service. Thank you!

Development History

Group Structure

01 SUNNY PLASTICS TECHNOLOGY LTD

02 CHANGZHOU HENGTE MOLDS AND PLASTICS MANUFACTURING CO.,LTD

03 CHANGZHOU KERTE PLASTICS INDUSTRY CO.,LTD

04 WUXI JIAYOU PACKAGING MATERIALS CO.,LTD

05 WUXI KAILIAN SPECIAL PLASTIC PACKAGING MATERIALS CO.,LTD

06 WUXI KANGTIAN INTERNATIONAL

Enterprise Advantages

Years of industry accumulation

-

Technical R&D and Innovation Strength

As one of the group companies, the integrated Sunny Plastics Technology has developed into an enterprise with more stronger strength in the ultra-precision mold and plastic packaging film industry with years of industry accumulation and technological innovation. It has won multiple praises in professional technology, product quality, market reputation and other aspects. Sunshine Plastic' s products are becoming more and more competitive in the market -

Group Strength and Brand Estatablishment

As one of the group companies, the integrated Sunny Plastics Technology has developed into an enterprise with more stronger strength in the ultra-precision mold and plastic packaging film industry with years of industry accumulation and technological innovation. It has won multiple praises in professional technology, product quality, market reputation and other aspects. Sunshine Plastic' s products are becoming more and more competitive in the market -

Building Market Networks and Brand Influence

With high-quality products and services, we have established a wide sales network both domestically and globally, and are gradually promoting the establishment of sales networks abroad. The product has been exported to multiple countries and regions and has received high praise from customers. Simultaneously focusing on brand building and market promotion, enhancing brand awareness and influence through participating in industry exhibitions, hosting technical seminars, and other means. These efforts not only enhance the company‘s market competitiveness, but also provide customers with more convenient and efficient services. -

Product quality and strict quality control

Regard product quality as the lifeline of the enterprise. We have established a comprehensive quality management system and strict quality control standards from raw material procurement to production process control, product testing, and after-sales service. By introducing first-class testing systems and advanced production processes, we ensure that every product meets national and industry standards, providing customers with high-quality, high-performance, and reliable products.

简体中文

简体中文

首页

首页

Our Business

Our Business  News

News  Contact

Contact